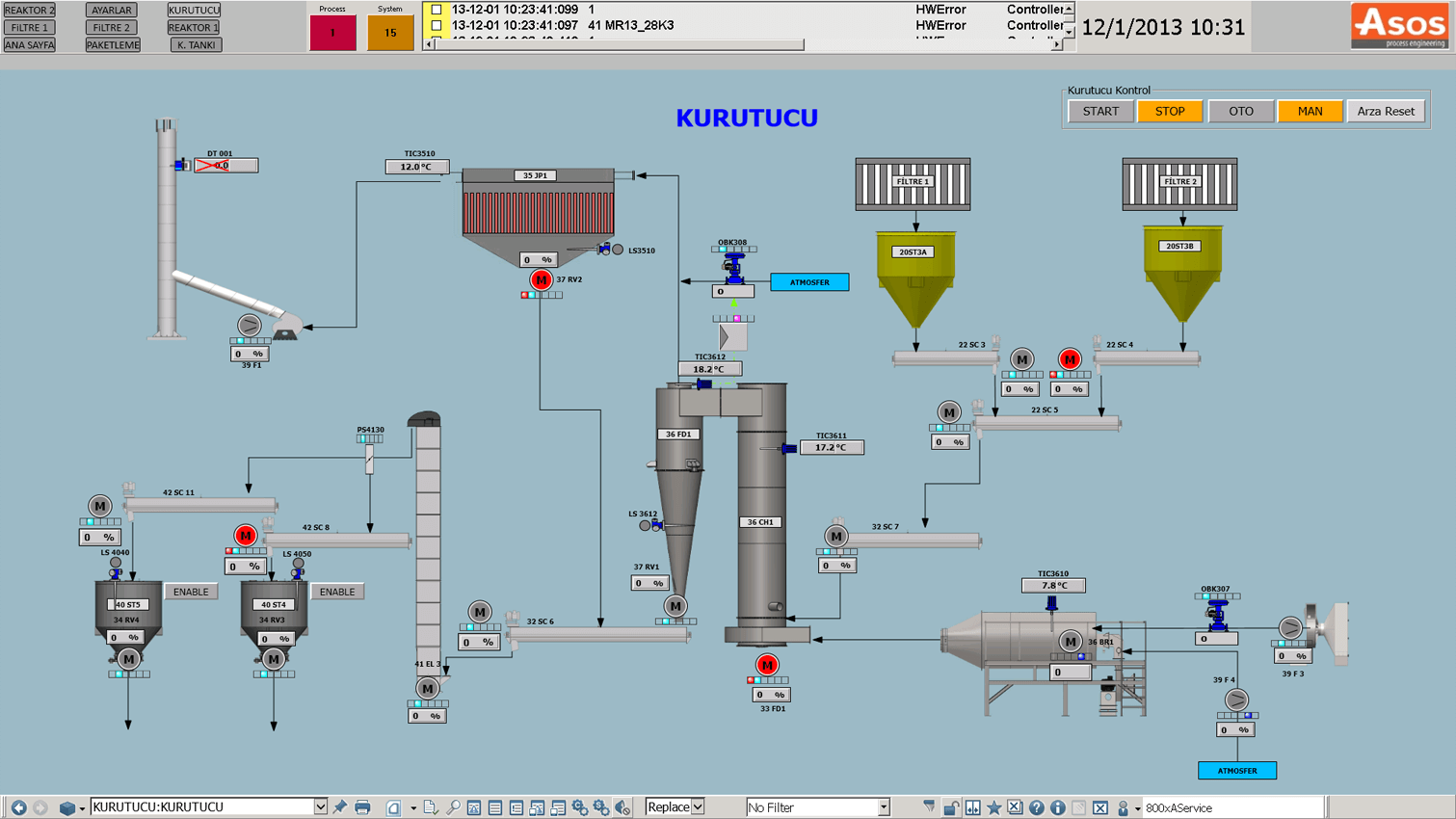

FLASH DRYERS:

Flash dryers are the most cost-effective systems for dry products that inherently have low humidity content or are dewatered. Also known as "pneumatic dryers", these systems perform the simplest gas suspension as they occupy small places. In only one go, they perform blending, heat transfer and bulk transfer operations together to dry a solid material. Product usually remains in the dryer less than 3 seconds.

- Short remaining period.

- If necessary, a buffer bunker or back blending system may be added.

- They may be designed for open-circuit, partial gas recovery and SSD ™.

- They are designed to be operated in an inert atmosphere.

- Simple design with a few moving parts

Advantages

- Ensures product quality.

- Perfect choice for processing heat sensitive or easily oxidized feeding materials.

- Provides energy savings and ensures system integration.

- Affordable, low maintenance and cleaning requirements.

- Product or product grade may be changed easily with minimum downtime.