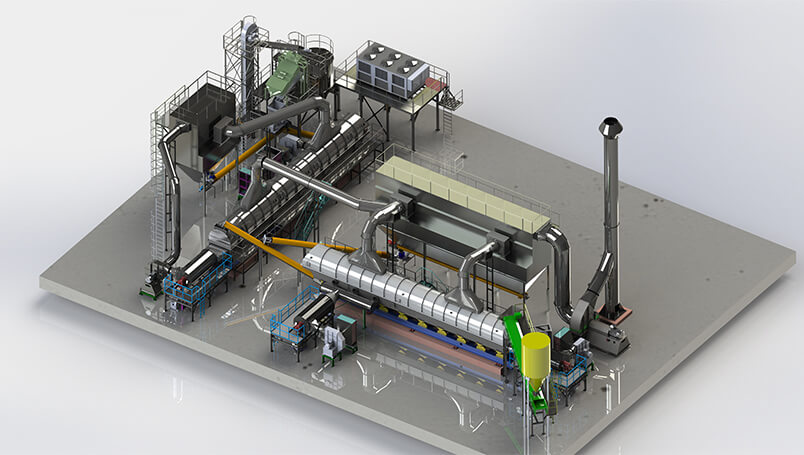

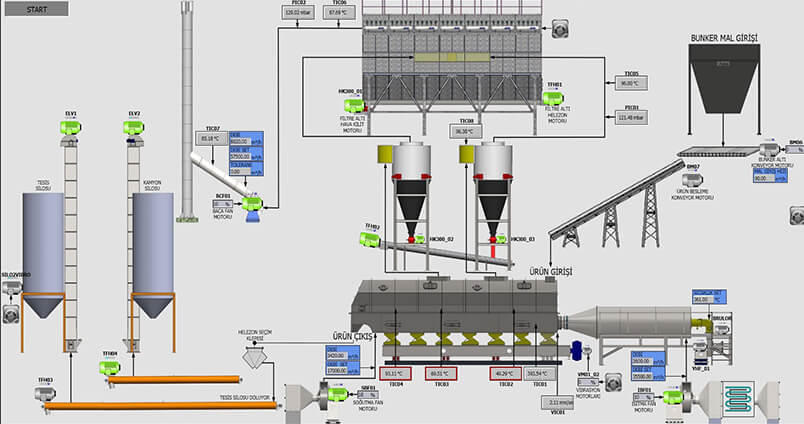

FLUID-BED DRYERS:

Fluidization is a process whereby pressurized air is passed, by the virtue of a fan, through the granular material to be fluidized at high speed against the force of gravity to keep the granules suspended. Suspended product forms a homogeneous composition. This ensures maximum efficiency in product to be dried. Fluid bed dryers and coolers are an ideal solution for the aggregate and mineral industry. Drying systems for minerals and aggregates consume a large amount of energy, leading to high operating costs and low margins. Due to the abrasive properties of the workpieces, wear and tear also mean frequent maintenance and repair or replacement costs. These costs have been reduced to a minimum due to the Fluid Bed Dryer. Fluid bed dryers offer a 25-30% reduction in energy costs compared to other dryers due to the working principle. Fluid Bed Dryers with a heat recovery system have an important role in energy efficiency by recovering the hot air they get from the hatch.

Fluid-bed dryers are best for granular and crystal materials.

The Benefits of Vibrating Fluid-bed Dryers:

- Lower energy consumption compared to other dryers

- Power source as per different fuel types

- Drying multiple products in the same drying process

- Cooling on the same body

- Rapid and uniform heat transfer

- Shorter drying time

- Dries products of diameters from 50 micron to 5 mm

- Drying at low temperature