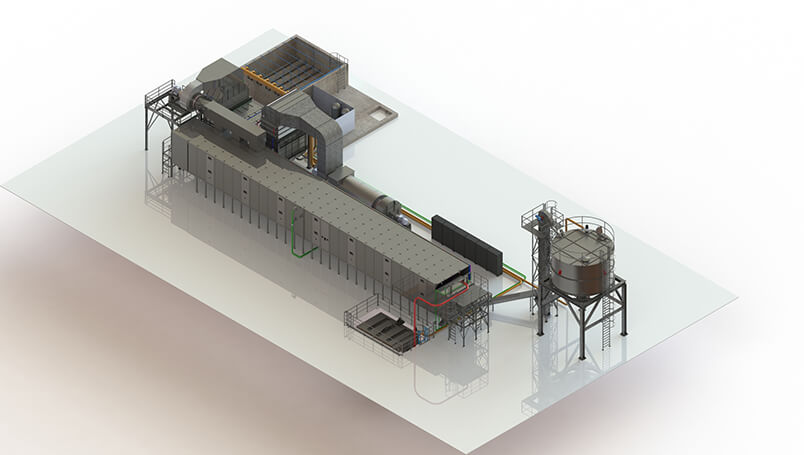

ROTARY BELT DRYERS:

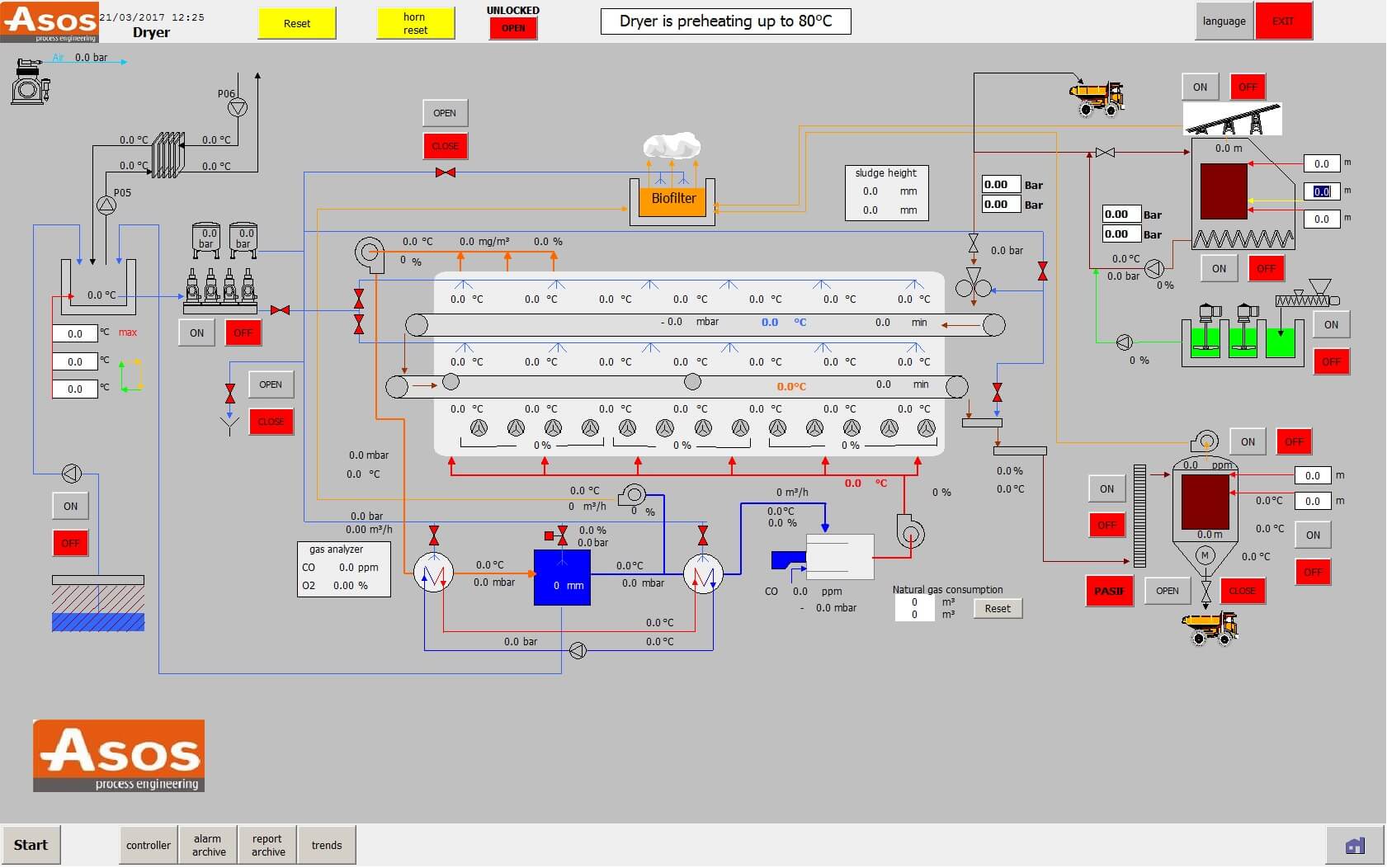

Rotary Belt Dryers are used to dry products while they are being moved horizontally with the help of fans through a system which consists of steel pallets bedded over a chain and isolated chambers. Rotary Belt Dryers are mainly used in the biomass sector for wastewater sludge, fertilizer, sawdust, tree bark etc. is a preferred type of dryer in drying processes in products.

With Rotary Band Dryers, 25% dry matter rates in wastewater sludge can be withdrawn up to 90% dry matter rates. The reasons for drying the sludge are reducing the amount of water in the sludge and thus the amount of sludge, to increase the calorific value of the slurry, thereby facilitating the burning of the slurry without using additional fuel, clean the sludge, to stabilize the sludge, to obtain a fertilizer and high market value sludge, such reasons.

Advantages

- Designed to dry granular products with or over a diameter of 20 mm, or sludge products in macaroni form.

- Maximum yield for high moisture and hard-dry products thanks to extended kiln-drying time.

- Various drying periods with adjustable speed belt system

- Belt system made of special steel

- High-flow circulation fans

- Isolated chambers

- Compact and robust stainless steel design

- Low maintenance and long life