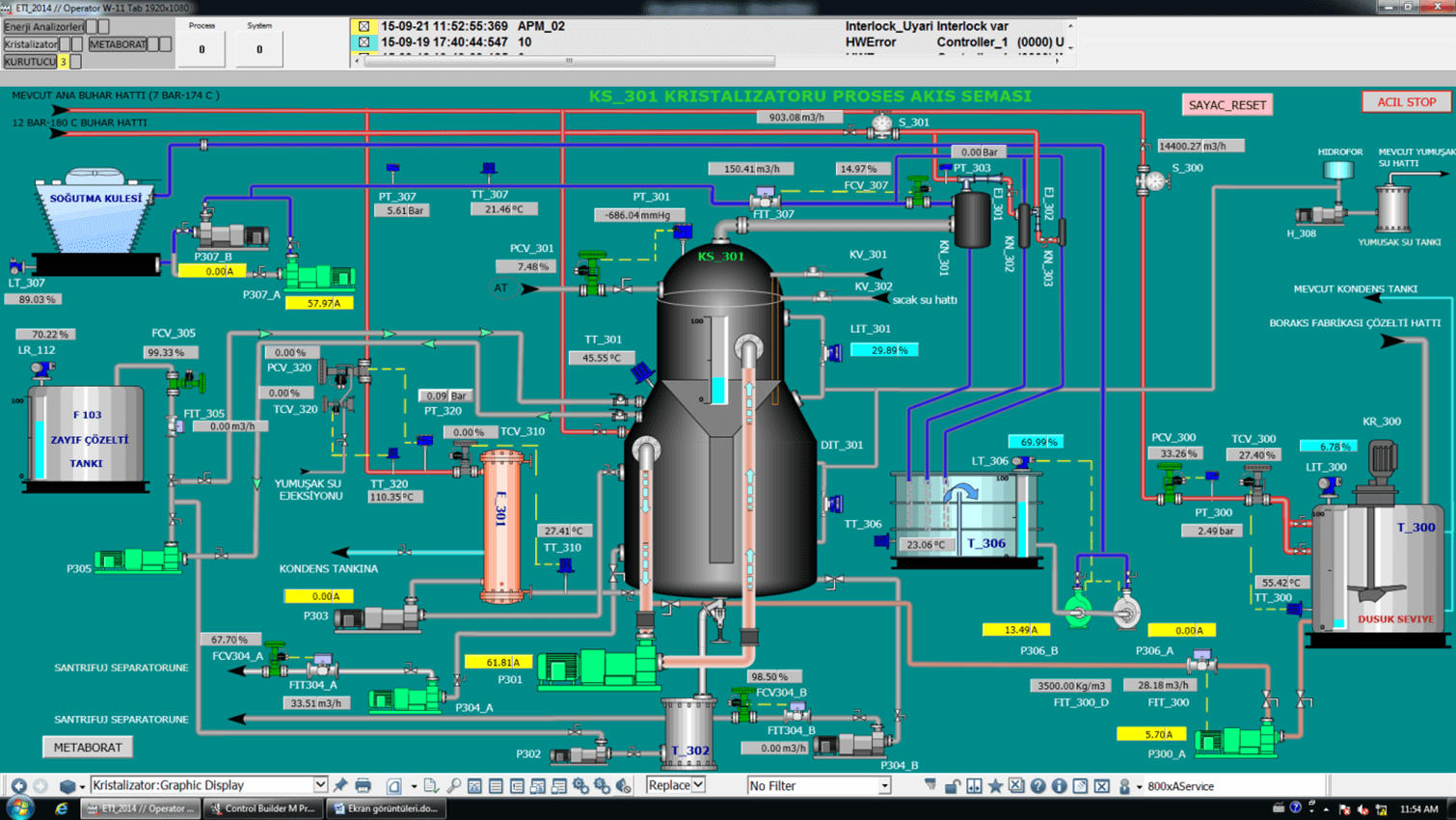

KRISTALIZATOR:

A wide range of crystallizers are used in process industry. It is common in batch processes to use stirred tanks cooled by cooling water passing through outer jacket or inner spiral. DTB, natural circulation type, forced circulation type and Oslo type crystallizers are the most commonly used crystallizers in continuous crystallization processes.

Design of a crystallizer type of which is chosen according to the process and flow rate of which is known ensures primarily determination of its active volume (waiting period) as well as its interior design, dimensions and auxiliary components.

ASOS Company identifies technologies that best fits to the process needs in industrial-type crystallization designs.

-

Factors ensuring product properties and cost-effective production in identifying crystallizer types are given below:

- Product length

- Product quality (impurity, storage and other important physical properties, etc.)

- Process economy

- Size of operation

- Balancing mass and heat

- Specifying waiting period ensuring product properties

- Determining crystallizer dimensions according to design criteria

- Calculation of heat transfer surface (if any) and circulation rate

Our Process Equipment

- Oslo Type Crystallizer

- Force-Circulation Type Crystallizer

- Decomposition Type Crystallizer

- Draf Tube Baffle (DTB) Type Crystallizer